Battery component technology

High precision component technology

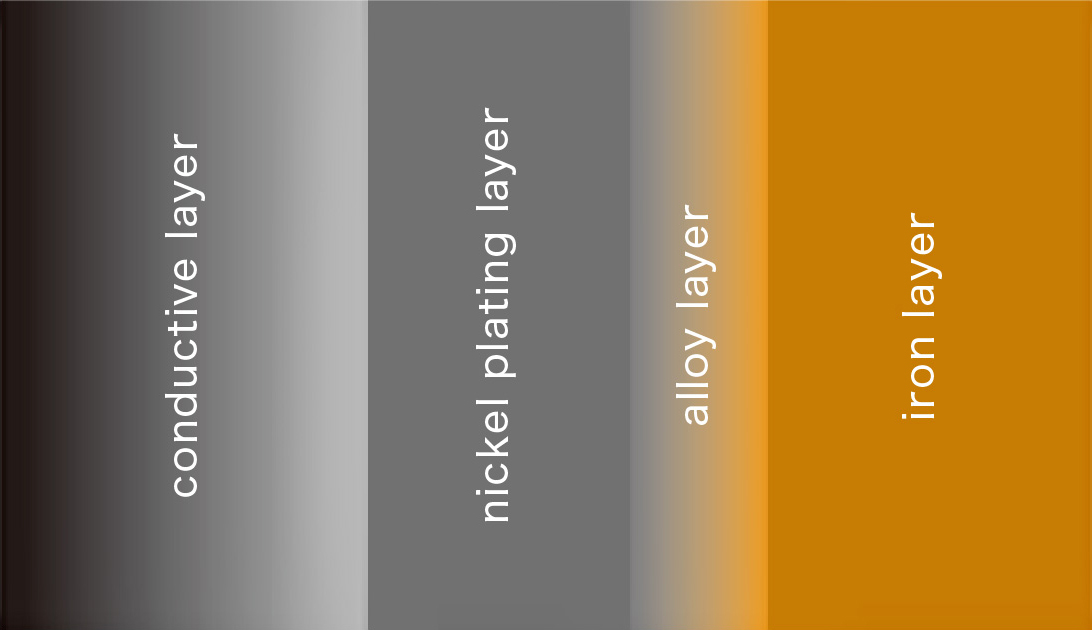

The positive electrode cans (exterior cans) used in batteries containing alkaline electrolytes are made of inexpensive Fe as shown in the figure on the right, and have protective layers (alloy layer and nickel plating layer).

By utilizing a protective layer, the adverse effect of Fe on battery performance is reduced, and stable battery performance is realized over long periods of time.

By utilizing a protective layer, the adverse effect of Fe on battery performance is reduced, and stable battery performance is realized over long periods of time.

Image of inside the positive electrode can

FDK's original technology

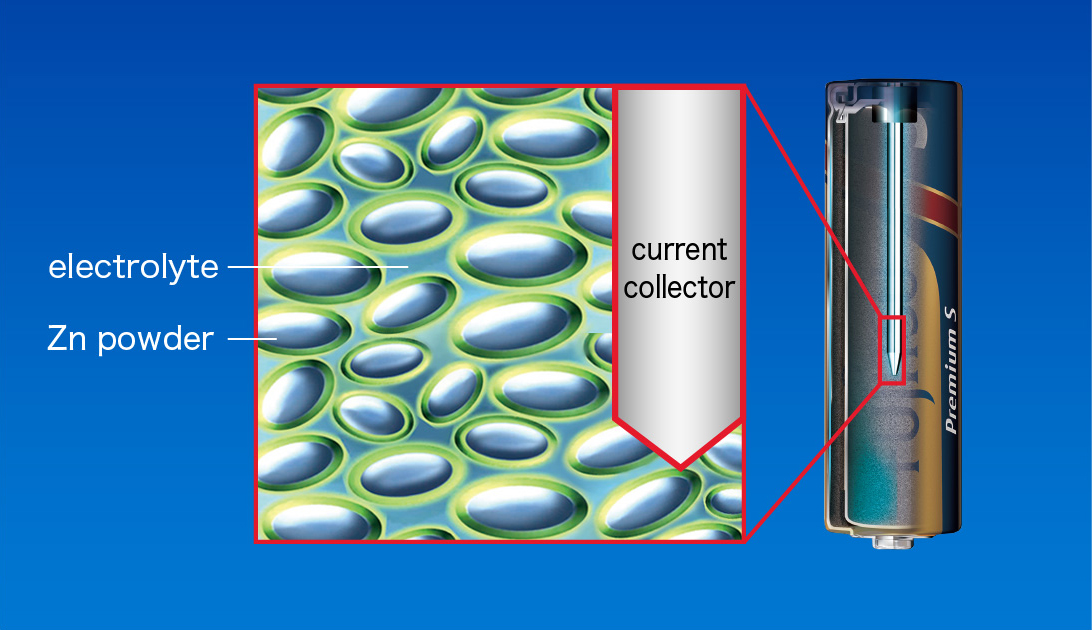

As shown in the figure, FDK has improved our current collectors and positive electrode cans, and we have developed an alkaline battery that is device-friendly and can be used for a long period of time.

Using this component technology, Premium S achieves three battery characteristics that are often requested by our customers.

Using this component technology, Premium S achieves three battery characteristics that are often requested by our customers.

- Extend battery usage time

- Maintain power after long storage

- Prevent cell leakage

Image of the positive electrode can

New plating is used in the current collector

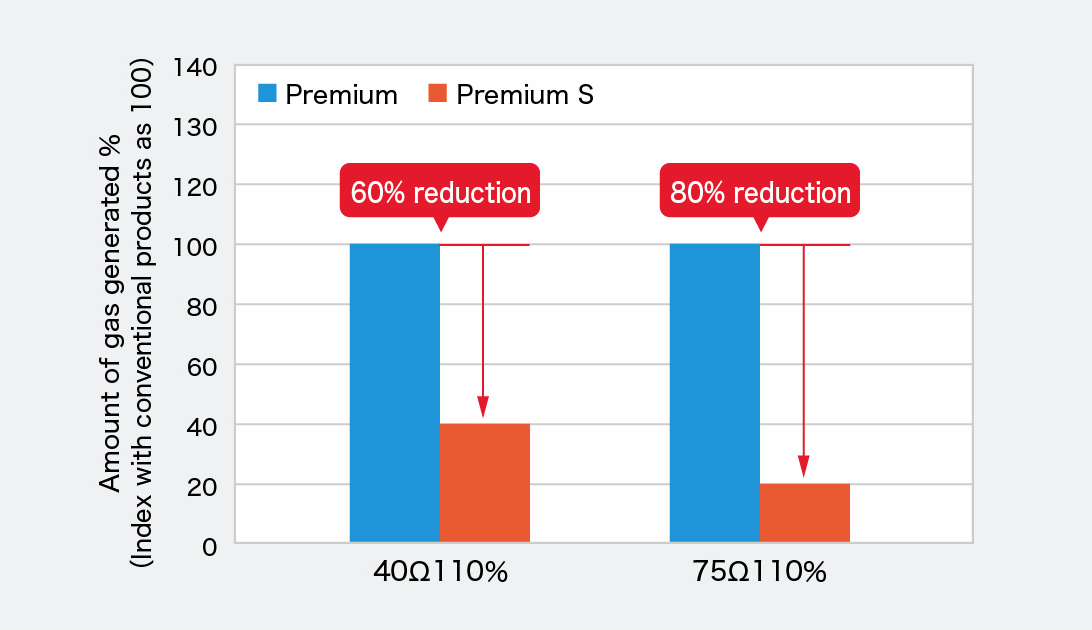

Premium S, which uses our new plating, significantly reduces the gas generated from the Zn negative electrode and improves battery leakage resistance.

Negative electrode gel internal image

Amount of gas generated in the battery after over-discharging

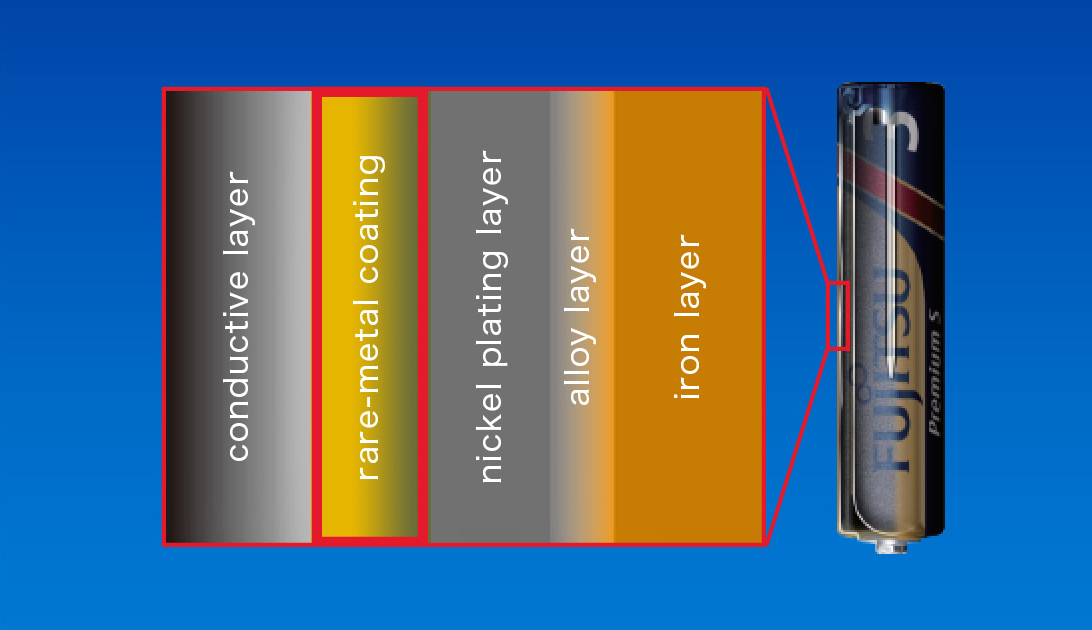

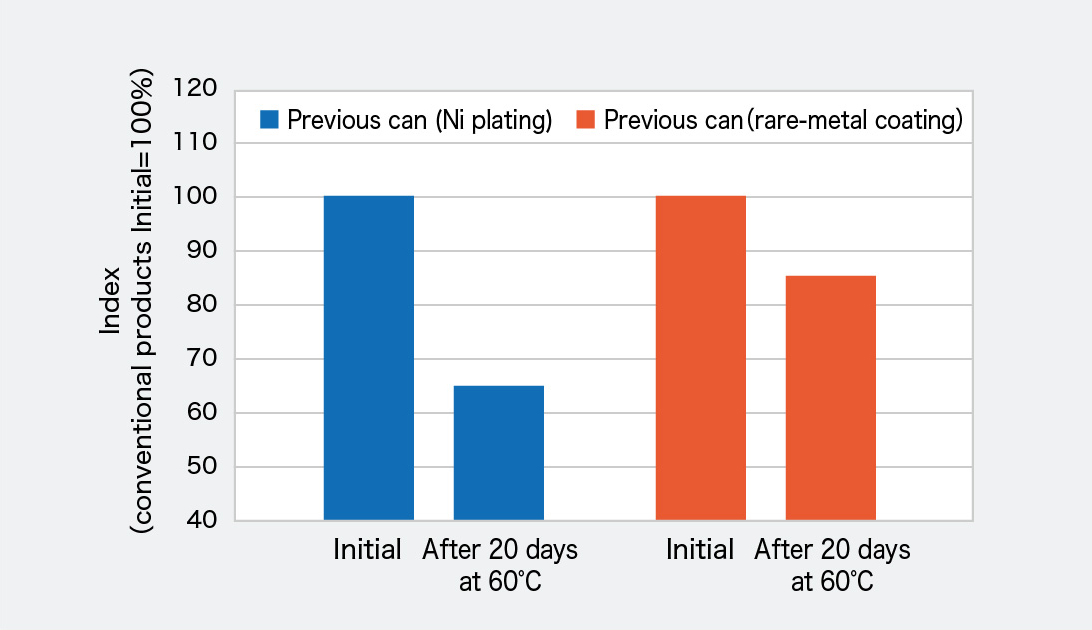

Rare metal coating on positive electrode cans

By applying a rare metal coating to the positive electrode can as shown in the figure, the battery capacity is maintained even after long-term storage, making it an ideal battery for stocking of emergency supplies.

Premium S positive electrode can with rare metal coating

Comparison of discharge performance after long-term storage (accelerated test)