| Chinese language |

||||||||||

| Development of high-capacity AB2 type hydrogen storage alloy for hydrogen

storage tanks - We will meet the needs of the coming hydrogen generation with hydrogen storage alloys that combine ease of handling with high-density storage - |

||||||||||

|

|

||||||||||

| July 17, 2025 FDK CORPORATION |

||||||||||

| FDK CORPORATION (Tokyo Stock Exchange Standard Market: Code 6955) has developed a new high-capacity AB2 type hydrogen storage alloy as a new material for hydrogen storage tanks aimed at realizing a hydrogen energy generation. | ||||||||||

|

||||||||||

| Background and Technological Strengths Since 1991, we have been manufacturing and selling nickel-metal hydride batteries with features such as wide temperature range, rechargeable and reusable, high recyclability(*1), and high safety(*2) for various applications such as security, automotive, medical devices, and home appliances. The hydrogen storage alloy used in the negative electrode of nickel-metal hydride batteries has an overwhelmingly high-volume efficiency, with a volume for storing a certain amount of hydrogen that is approximately 1/2 that of liquid hydrogen and approximately 1/7 that of high-pressure hydrogen gas. In addition, it can store hydrogen stably at near room temperature and atmospheric pressure, making it an important product that is attracting attention as a key component in the coming hydrogen movement. In 2024, BAOTOU FDK CO., LTD., which develops and manufactures hydrogen storage alloys, joined our group, and we have been developing hydrogen storage alloys for hydrogen storage tanks by leveraging our long-cultivated technological capabilities in the development of hydrogen storage alloys for batteries. Features of the New Product, AB2 Type Hydrogen Storage Alloy Currently, AB5 type hydrogen storage alloys, which are mainstream for battery applications, excel in terms of ease of activation(*3), fast reaction speed, and ease of recycling. However, they are not suitable for tank applications that require larger storage capacities due to their low hydrogen storage capacity per unit weight. Furthermore, hydrogen storage alloys other than the AB5 type that excel in hydrogen storage capacity have issues with usability, such as a significant decrease in hydrogen release pressure during use(*4) or a complicated activation process(*3). In order to address these needs and issues, we have developed a high-capacity AB2 type hydrogen storage alloy that is easy to use for hydrogen storage tanks. The newly developed AB2 type hydrogen storage alloy has the following features:

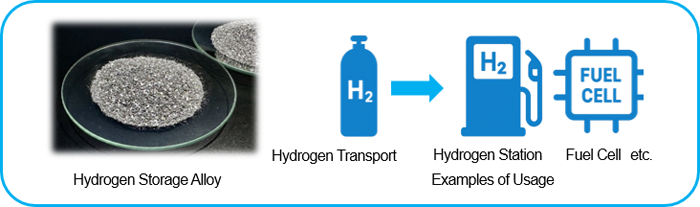

Future Developments Samples of this product will be available to select customers starting in July 2025, with mass production scheduled to begin in October 2025. In addition, we will exhibit AB2 type hydrogen storage alloy at the 2025 China (Shanghai) International Hydrogen Energy and Fuel Cell Technology Exhibition (http://www.expoquanqiu.com), scheduled to be held at the National Exhibition and Convention Center in Shanghai, China, from Tuesday, July 29 to Thursday, July 31, 2025. FDK, as a Smart Energy Partner, will continue to provide customers with proposals for the efficient use of electric energy and hydrogen energy in a safe and efficient manner by assembling advanced technologies. Main Applications of Hydrogen Storage Alloys for Hydrogen Storage Tanks The main applications of hydrogen storage alloys for hydrogen storage tanks are hydrogen storage tanks for hydrogen stations, fuel cells, small fuel cell mobility, etc.

|

||||||||||

|

||||||||||

| [Close] | ||||||||||

|

|

||||||||||

| Terms of Use | Privacy Policy | ||||||||||